Des solutions de toiles tissées pour un monde meilleur

Notre ambition de leader du marché à la pointe de la technologie

Pouvons-nous rendre la planète plus saine, plus propre et plus sûre ? Nous disons : oui.

Avec des solutions de toiles tissées techniques destinées à l’ industrie et à l’architecture, dont les avantages et les possibilités d’utilisation s’imposent dans un nombre croissant de secteurs et d’applications.

Chez GKD, nous contribuons à cette évolution depuis près de 100 ans. Nous accompagnons nos clients et les soutenons en notre qualité de partenaire innovant et de leader technologique mondial. Nous sommes des conseillers – engagés, fiables et proches. Nos temps de réaction sont courts, nos normes pour les produits sont élevées et nos exigences ne cessent de croître. Et nous sommes LES experts en matière de résolution de problèmes dans nos secteurs grâce à des solutions parfaitement adaptées à nos clients et à nos marchés.

Entreprise familiale depuis quatre générations, nous avons toujours agi avec clairvoyance. Nous sommes convaincus de pouvoir et de devoir prendre nos responsabilités dans nos actions : pour nous, pour nos clients et pour la planète.

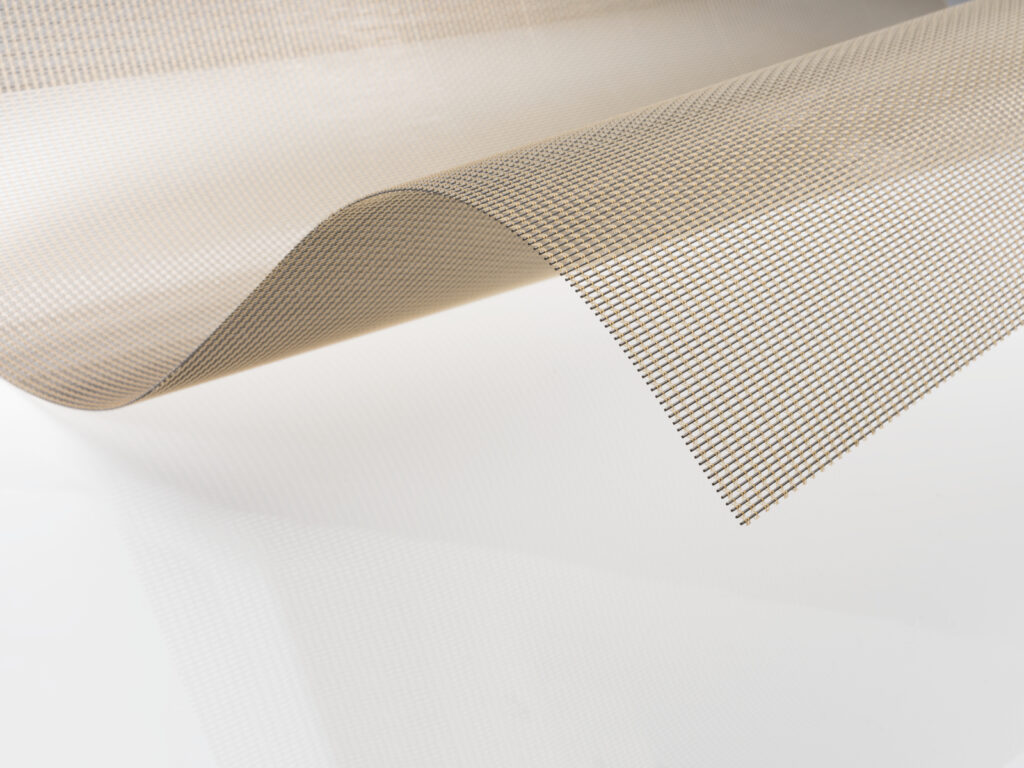

GKD Tissus industriels

Notre objectif – la solution adaptée à votre application

Depuis le début, nos produits sont également des solutions aux défis d’une production efficace. Nos tissus de pointe et nos solutions de filtration en métal, en fils synthétiques et en fibres techniques garantissent un avantage concurrentiel dans de nombreuses applications industrielles et permettent d’atteindre les objectifs de durabilité. Découvrez la diversité inégalée de nos produits – et la solution parfaite pour vous.

GKD Tissus pour l’architecture

Une esthétique intemporelle avec une fonction aux multiples facettes

Depuis des décennies, nos tissus architecturaux servent de référence pour la conception de bâtiments – à l’extérieur comme à l’intérieur – et combinent les exigences esthétiques les plus élevées avec des fonctions d’ombrage, d’acoustique et de protection. Nos tissus design fabriqués individuellement et nos composants système normalisés ont une durée de vie fiable et offrent aux architectes et aux planificateurs non seulement un maximum de sécurité, mais leur confèrent également une marge de manœuvre créative.

Carrière chez GKD

Notre vision – votre perspective

Notre vision d’entreprise globale FOR A HEALTHIER, CLEANER, SAFER WORLD nous anime et nous motive au quotidien.

Cette vision vous offre les meilleures perspectives professionnelles et de carrière. Quelle que soit la phase de votre carrière professionnelle dans laquelle vous vous trouvez actuellement. Nous recherchons des personnes qui enrichissent notre culture. Qui apprécient notre mélange de tradition et d’internationalité. Qui s’investissent. Qui s’engagent avec nous sur la voie d’un monde plus sain, plus propre et plus sûr.

WEAVE YOUR CAREER.

GKD dans le monde entier

Proche de nos clients et de nos marchés

Le siège de notre entreprise se trouve en Allemagne. Afin d’être proches de nos clients et de nos marchés et de pouvoir garantir des normes homogènes au niveau mondial, nous produisons également aux États-Unis, au Chili, en Afrique du Sud, en Inde et en Chine. Nous avons également des filiales et des représentations en France, en Espagne et à Dubaï.

Notre ambition. Dans le monde entier.

Depuis près de 100 ans.

FOR A HEALTHIER, CLEANER, SAFER WORLD

1925

fondation par

Josef Kufferath

à Düren

7

sites de production sur

quatre continents, représentations

dans le monde entier

900

collaborateur trices dans le monde entier

130

millions d’euros de chiffre d’affaires en 2023