Technical woven solutions

for a better world

Our vision and commitment as market and technology leader

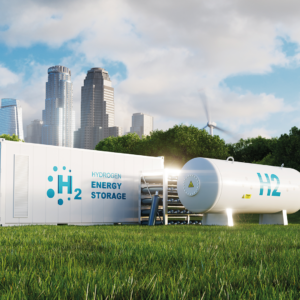

Can we make the planet healthier, cleaner, and safer? Our answer is a resounding yes!

With technical mesh and fabric solutions for industry and architecture, whose benefits and range of potential uses are gaining ground in more and more sectors and applications.

At GKD, we have been a driving force behind this development for almost 100 years. We accompany and support our customers as an innovative partner and global technology leader. We are consultants – engaging, reliable, and nearby. Our response times are short, our product standards are high, our aspirations are constantly growing. Since we offer perfectly tailored solutions for our customers and markets, we are also THE problem solving experts in our sectors.

As a fourth generation family-run business, we have always adopted a far-sighted approach. We feel certain that we can and must assume responsibility in everything that we do: for us, for our customers, and for the world.

GKD Industrial Mesh

Our focus – The right solution for your application

Right from the outset, our products have also been solutions to the challenges of an efficient production. Our state-of-the-art mesh fabric, and filtration solutions produced from metal, synthetic wires, and technical fibers ensure competitive advantages in many industrial applications, and the achievement of sustainability goals. Discover our unrivaled range of products – and find the perfect solution for your application.

GKD Architectural Mesh

Timeless aesthetics with function in numerous facets

For decades, our architectural metal fabrics have been setting standards in the design of buildings – both externally and internally – where they combine the ultimate in aesthetics with shading, acoustic, and protective functions. Our individually produced design fabrics and standardized system components offer durability that customers can rely on – not only providing architects and planners with maximum safety, but also opening up scope for creative designs.

Careers at GKD

Our vision – Your perspective

Our global corporate vision FOR A HEALTHIER, CLEANER, SAFER WORLD drives us and motivates us every day.

This vision gives you the best career prospects, no matter what point in your career you are currently at. We are looking for people who enrich our culture. Who appreciate our mix of tradition and internationality. Who get involved. Who will join us on the path to a healthier, cleaner, safer world.

WEAVE YOUR CAREER.

GKD worldwide

Close to our customers and markets

Our headquarters are in Germany. To ensure close proximity to our customers and markets, while ensuring uniform global standards, we also have production operations in the US, Chile, South Africa, India, and China. In addition, we maintain further branches and representative offices in France, Spain, and Dubai.

Find out more

Our commitment. Worldwide.

For almost 100 years.

FOR A HEALTHIER, CLEANER, SAFER WORLD

1925

founded by

Josef Kufferath

7

production sites on

four continents and

representative offices all over the world

900

employees worldwide

130

million euros in revenue

in the year 2023